"StoneCold" (StoneCold)

"StoneCold" (StoneCold)

08/09/2014 at 19:25 • Filed to: None

4

4

9

9

"StoneCold" (StoneCold)

"StoneCold" (StoneCold)

08/09/2014 at 19:25 • Filed to: None |  4 4

|  9 9 |

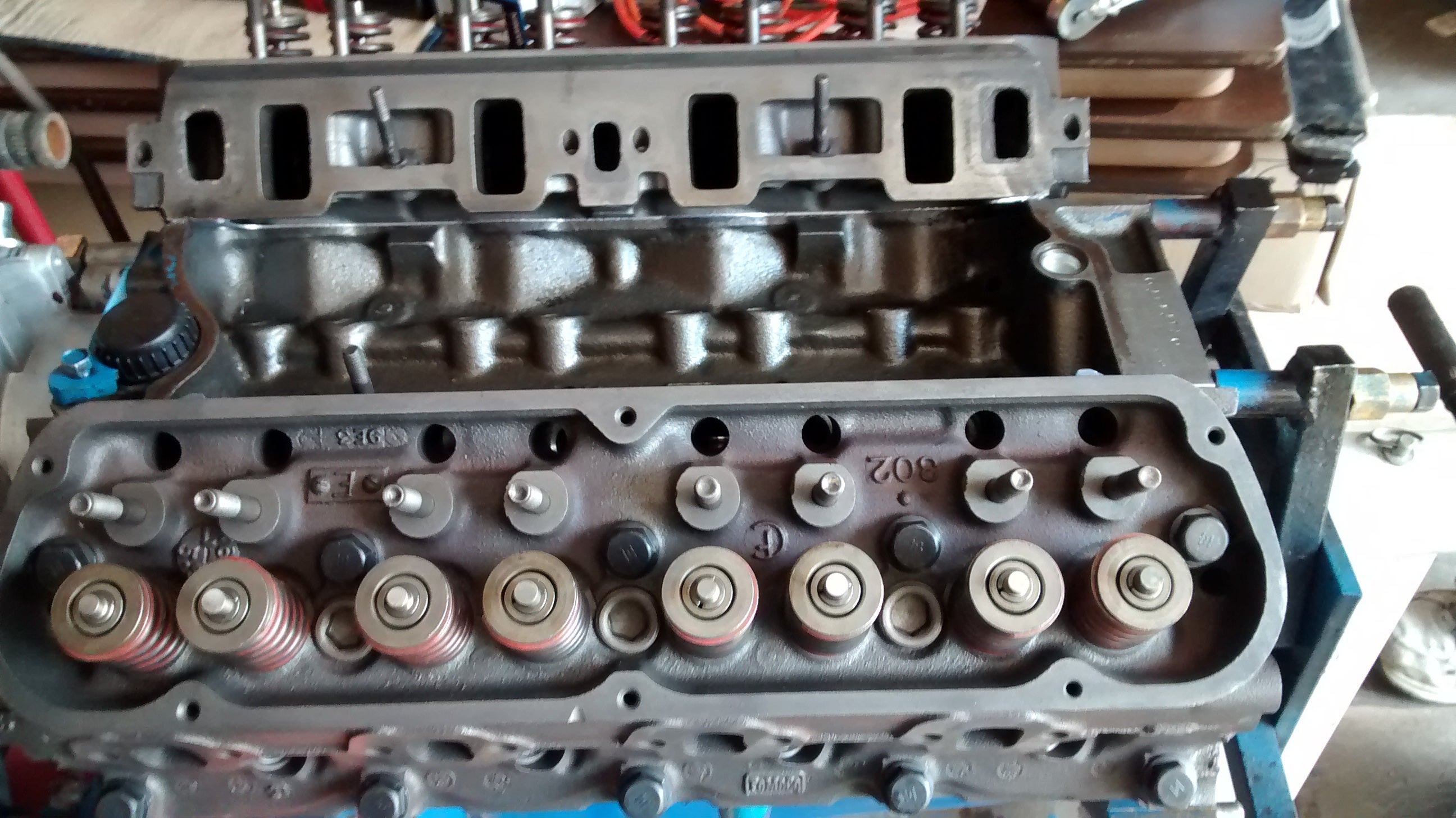

I finally got the heads back from the shop; time to put it all together! Do non-ARP head bolts need washers?

Thought I'd take a pic.

#ForeverFord

....

#ForeverAlone V_V

Zipppy, Mazdurp builder, Probeski owner and former ricerboy

> StoneCold

Zipppy, Mazdurp builder, Probeski owner and former ricerboy

> StoneCold

08/09/2014 at 19:32 |

|

I pulled apart a 302 before, out of a '91 Grand Marquis, and I'm guessing that's one of those, too?

StoneCold

> Zipppy, Mazdurp builder, Probeski owner and former ricerboy

StoneCold

> Zipppy, Mazdurp builder, Probeski owner and former ricerboy

08/09/2014 at 19:49 |

|

Indeed, this is a '69 , but they haven't changed too much in their lifetime.

sdwarf36

> StoneCold

sdwarf36

> StoneCold

08/09/2014 at 20:17 |

|

No. But put some oil on the threads + under the head of the bolt.

desertdog5051

> StoneCold

desertdog5051

> StoneCold

08/09/2014 at 20:21 |

|

Proper head bolts have a head that doubles as a flat washer. Don't skimp on this. Remember that most head bolts are torque to yield and should not be used again.

StoneCold

> desertdog5051

StoneCold

> desertdog5051

08/09/2014 at 20:25 |

|

So like a flange bolt, but a little on the thicker side? Check!

And we use old head bolts for bunches of other things (one of our outdoor benches is held together by 289 head bolts XD)

StoneCold

> sdwarf36

StoneCold

> sdwarf36

08/09/2014 at 20:26 |

|

Is the oil, like, 100% necessary?

I thought that was only ARP bolts...

>_>

sdwarf36

> StoneCold

sdwarf36

> StoneCold

08/09/2014 at 21:10 |

|

Yes. Friction is friction-manufacturer not withstanding.

A bolt has clamping force because it stretches- NOT because you are pulling hard on the wrench. (if all is well, pulling hard on the wrench gives it enough torque to stretch the bolt.)

Picture this: you have a rusty bumper bolt. You got the nut started-but by 1/2 way down you have to use a wrench to continue. The farther down the bolt you go, the more force you have to put on the wrench. The nut is still a 1/4" away from bottoming-and you are sweating away on the wrench to get it to go. You are applying 60 ft lbs. of torque-but you still have zero clamping force. Put a torque wrench on it-it clicks off at 60 lbs.-but the nut isn't bottomed. "But I torqued it to 60lbs." Well—you applied that much torque-but you were just overcoming the friction of the rust on the threads.

Manufacturers have no way to tell you a number if the threads are crappy-rusty-dry-etc. So the standard is to apply some oil on clean threads. This way, the 60 lbs. applied actually is making the bolt stretch.

I worked many years as a automotive machinist. My last job I was building many hi end race engines. Almost all use ARP rod bolt. You use the supplied moly lube on the threads. Now a days, a torque spec is "25 ft lbs plus 40 degrees". Its more telling that 40 degrees provide a more accruate measure of the stretch. (and we ALWAYS used a bolt stretch gauge to measure.)

I did some experiments because I had all the toys —a dry bolt-vr.s an oiled bolt-vs. moly. It took 30 lbs to get .005 stretch with moly—40 with oil—and 55 dry.

So long answer to a short question-if the book says use oil (and it does) then use oil.

StoneCold

> sdwarf36

StoneCold

> sdwarf36

08/09/2014 at 22:08 |

|

Well, they were torqued by the time I saw your first post. :(

They're down to about 70 ft-lbs according to the instructions (Victor Reinz), starting at 30 ft-lbs and going up by 10 until 70. I know it's a bad idea at this point to back them off.

I'll just have to keep running it.

The block isn't performance by any means though (Pretty much stock everything for 1969 and only a 2-barrel carb and stock intake).

Now I know for the future though, thank you!

sdwarf36

> desertdog5051

sdwarf36

> desertdog5051

08/09/2014 at 23:39 |

|

most head bolts are torque to yield and should not be used again.

Modern stuff—yes. Old school (like this) no.